Sheltered

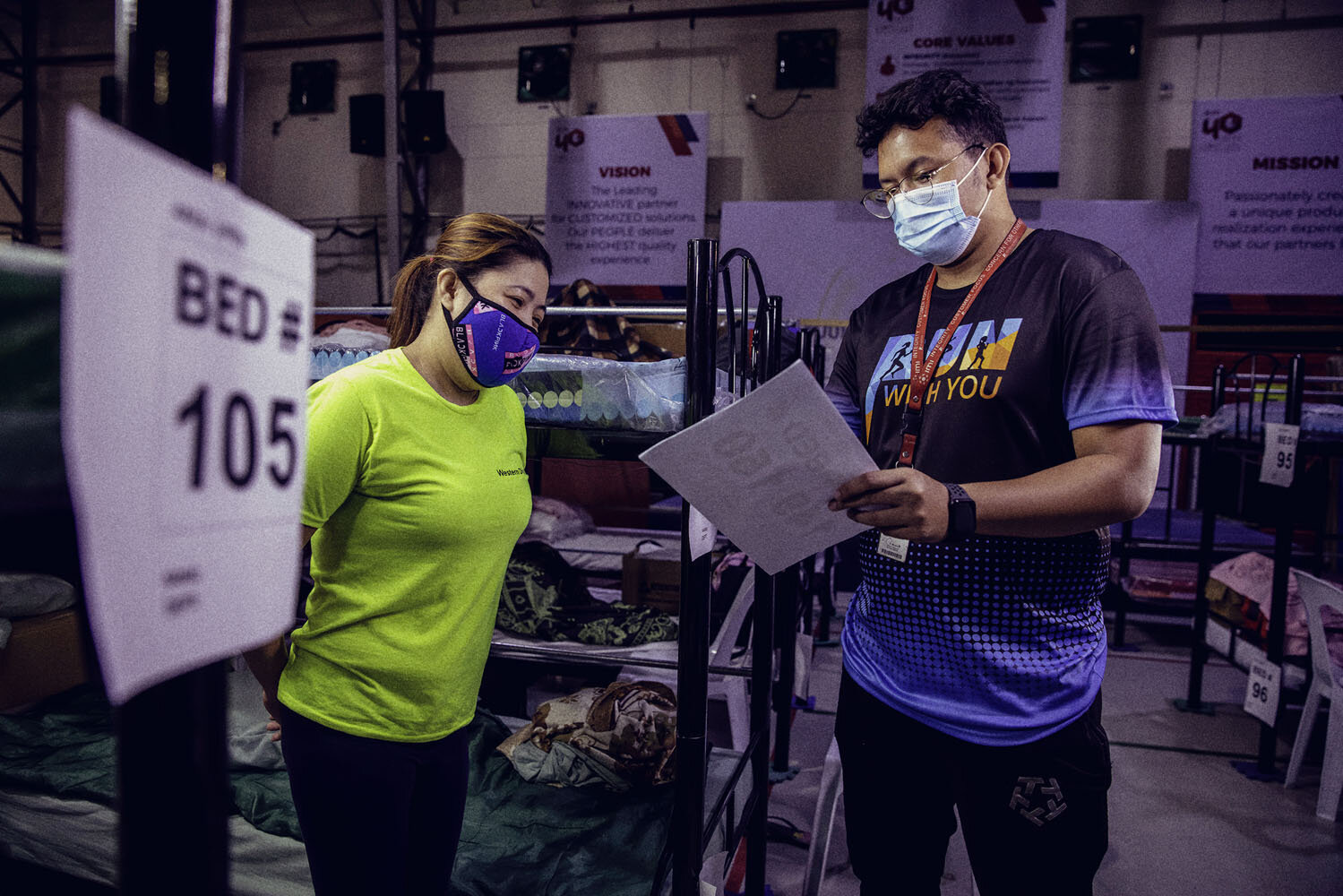

Carla Martinez and Adrian Alvero of Integrated Micro-Electronics Inc.’s hardworking Human Resources department went above and beyond their job descriptions to feed and house their workers—1,300 of them

Words by ALYA B. HONASAN

Adrian Alvero was exhausted.

It was a few weeks into the expanded community quarantine that had been declared over Manila and nearby provinces.. A Human Resources (HR) assistant at Integrated Micro-Electronics Inc. (IMI), he and his colleagues from housekeeping and HR had just moved 100 beds and about as many people from the IMI plant in Laguna Technopark, Biñan to the former Honda Cars automotive plant some 1.6 km away.

Adrian Alvero

IMI is the manufacturing portfolio of AC Industrials, Inc., a wholly-owned subsidiary of Ayala Corporation and one of the top technology solutions companies in the world. It makes components for life-saving medical devices, automotive sensors, and communications electronics, which are considered “essential goods and services.”

To continue production during the lockdown, IMI had decided to shelter its employees in place. That meant providing beds, toilet facilities, meals, hygiene kits, and medical services. With every available space at the IMI plant utilized, the company had to rent the canteen at the now-closed nearby car plant to accommodate more workers.

Adrian and company had been at it since 8 am, shuttling between the transfer, the distribution of beddings, and registration for new shifts of incoming employees at the main plant. A couple of hours before midnight, they sat on the curb near the entrance of the car plant, still managing to laugh about their situation. “Yung mga logistical na gawain, enjoy ko na rin kasi gustong-gusto ko talaga tumulong sa kapwa; makita lang namin sila na kumportable, nakakawala din talaga ng pagod,” he says.

“Minsan nga lang, di maiiwasan pag sobrang pagod, mapapa-upo ka na lang sa isang tabi. Kung puwede mo lang hatiin yung katawan mo, ginawa mo na. Pero kailangan talaga to serve the employees, kasi sila, nag-sakripisyo para makapasok, para matulungan ang company.”

““Minsan nga lang, di maiiwasan pag sobrang pagod, mapapa-upo ka na lang sa isang tabi. Kung puwede mo lang hatiin yung katawan mo, ginawa mo na.””

Making products that saves lives. JAZA, who visited the plant to check on the well-being of the IMI workers, stops to look at one of the factory’s products: the UCL Ventura Flow Generator, which can help COVID-19 patients breathe more easily and prevent the need for invasive ventilation.

Across the Ayala Group, other employees and partners were also sheltering at their workplaces. Security personnel and technicians hunkered down in shutdown malls just to make sure the premises were looked after. Power and water utilities personnel didn’t leave their posts for three months to make sure basic services were uninterrupted. Property managers nestled in the residential communities they managed. And essential security personnel, engineers, and technicians became instant families as they lived together for a quarantine period that stretched for three months. All were united in a commitment to serve and to keep each other safe.

Go-to Person

For Site HR Business Partner Carla Martinez, in charge of HR operations for an organization with as many as 1,400 employees, working from home didn’t mean having it easy.

“Even before the pandemic, we were the go-to persons for both employees and management. But the pandemic made us realize the frontline nature of the roles we play, with the employees who are working both on-site and off-site. So hindi tumitigil yung mga email, phone call, text messages ng mga tao —they were asking about assistance, how to process their loans. It was our job to answer them with the right information.”

“Working at her dining table at home after her children were asleep, Carla still felt guilty about not being physically present—even after she found out quite belatedly that she was pregnant.”

Even before sheltering in place began, Carla was getting texts as early as 4 AM, as she coordinated transport for a skeleton work force of about 300 during the first 15 days of the lockdown.

And then there were concerns like food, health protocols, and keeping track of positive COVID-19 cases in the barangays where employees lived. Working at her dining table at home after her children were asleep, sometimes until the wee hours, Carla still felt guilty about not being physically present—even after she found out quite belatedly that she was pregnant. “Nako-konsensiya ako kasi remote lang ako at nag-uutos, so sabi ko ito na lang ang contribution ko.”

A global company with some 17,000 employees all over the world, IMI had its own business continuity preparedness (BCP) plans in place, recounts Carla, but these were for fire and natural calamities like earthquakes. In fact, IMI was still dealing with the aftermath of the eruption of Taal Volcano, 72 km away in Batangas, last January 12. “We were doing relief operations for our affected employees, yung mga hindi nakapasok kasi stranded pa sila sa mga area na malapit sa Taal.” Carla also had to oversee cleaning because of the ashfall that blew their way.

And then, the pandemic happened. “Walang nag-expect na may darating na ganitong health hazard,” Carla says. “This was really different; pati yung hinanda nila for SARS, parang katiting lang nung requirements para dito sa COVID-19.”

From the beginning, their top concern was the health and safety of their employees. “Every day, every hour yata may meeting kami to address kung anong gagawin kung magkaroon ng case, o paano siguraduhin na hindi magkakaroon.”

““This was really different; pati yung hinanda nila for SARS, parang katiting lang nung requirements para dito sa COVID-19.” ”

Final exams. All IMI employees were tested for COVID-19 before they were allowed to return home. Healthcare workers visited the factory to collect their medical history and blood samples, which were then sent to the laboratory.

While IMI took all the necessary precautions to protect their employees, from wearing masks to social distancing and stricter security, Carla couldn’t help growing more concerned as the quarantine dragged on. “Hindi ako makatulog,” she says, her mother’s instinct kicking in as she thought of all the employees under her wing, and the risks associated with travel.

However, IMI also had a responsibility to customers, especially those working in the medical field. Now more than ever, they had to continue manufacturing products that could help in the global fight against the pandemic. How could they serve their customers, and protect the employees?

Around March 27, Carla recalls, management decided to shelter an initial number of workers to minimize the risks associated with travel. “Management decided that it might be better for the workers to be taken care of inside the plant, where they could be quarantined and given medical assessments bago sila pumasok). Aalagan talaga sila with free rice meals so they didn’t need to worry about their food and vitamin C supply, and with 24/7 medical staff.”

The effort was even noted in the IMI website among other global COVID-19 measures, such as how IMI Mexico created an app to monitor work hours for home-based employees, or how IMI Czech Republic initiated the sewing of face masks for use by employees as well as people in nearby communities.

Thus began the lightning-speed logistical coordination in Laguna. First, the airconditioned multi-purpose hall-cum-basketball court was set up with 100 beds for female employees, who made up 70 percent of the work force. “Nilatagan namin siya ng mga mattress, pero dapat may distance na 2 meters,” recounts Carla. “Hindi namin pinapayagan na dumikit-dikit.” . Wi-Fi was provided so employees could keep in touch with their families.

Roommates. The IMI basketball court was converted into a giant dorm, complete with beds and all the supplies the employees needed.

Ten bathroom cubicles were set up in the hall, but as more and more employees began to stay in, more spaces—offices, function rooms, and the aforementioned rented canteen at Honda—were converted into sleeping quarters. At one time, as many as 300 mattresses were delivered in one day. “Para nang stockholder ng Uratex yung boss ko,” says Carla, referring to the foam manufacturing company.

At the peak of the shelter-in-place operation, IMI was housing, feeding, and taking care of some 1,300 people. “Kung baga sa hotel, fully booked na talaga,” Carla recalls. But incredibly, it only took about four days between approval of the operation and the time the first IMI employee checked in.

Carla’s days were spent orienting employees brought by the company shuttle service, allocating beds, organizing laundry service, and keeping track of additional expenses. A small store for employees was set up in the multi-purpose hall to minimize people traffic in the canteen, where kitchen staff was also sheltering in place.

#AyalaCitizen Diary: Handrails and other high-contact areas are disinfected regularly. Anyone who enters the facilities must pass through a disinfection booth, wash their hands at the well-equipped handwashing station, and then step on a shoe sanitizing unit.

The heart for the job

The toughest part, Adrian says, was coordinating arrivals of new stay-in workers, who, as a rule, could not mingle with longer-staying employees for the next five days. That, and addressing the endless concerns that came with an operation of this magnitude, like airconditioning and shower facilities.

After almost two months, Adrian finally got to bike home for the first time to visit his parents, who were only too happy to see him safe. He immediately went back to work, however, because he knew his IMI family needed him. “Yung puso sa trabaho , yung commitment to work, management, and company—kung wala yon, sa tingin ko ‘di ko talaga magagawa.

“Yung isang mabigat na trabaho, pinayagan ka nilang i-handle…Yung support ng management and HR, nandoon talaga. ‘Di lang kami magkakatrabaho, naging pamilya kami.”

Homeward Bound. After clearing the COVID-19 test, Adrian bikes home to visit his parents.

““What kept me going was, yung alam mo na yung mga kasama mo nandoon on the ground, tapos ginagawa nila yung trabaho nila.” ”

Carla, for her part, had started out as a recruitment assistant at Honda Cars Makati in 2005. When she bought a home in Sta.Rosa, she says, “I prayed hard and searched for an Ayala company in the south! I had a good experience with their culture of helping Filipino communities.”

In spite of her work-from-home assignment, this wife and mother of two (not counting the one on the way) made a quick visit to the plant last Easter Sunday, when there was no traffic and few people. “What kept me going was, yung alam mo na yung mga kasama mo nandoon on the ground, tapos ginagawa nila yung trabaho nila.”

“The truest manifestation of character is revealed through crisis. Akala ko quote lang yun, eh totoo pala, kasi ang dami kong discoveries sa sarili ko at sa mga nakakasalamuha ko sa work. The best thing i can do is to also be there for them and for our co-employees who need us.#

PUBLISHED AUGUST 26, 2020